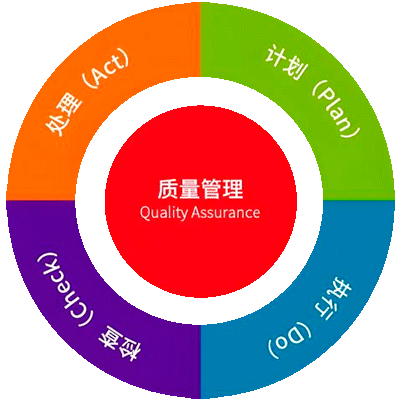

QUALITY MANAGEMENT

QUALITY SYSTEM

We perform relative full inspection and sampling inspection on products during the production process according to the actual requirements of the production process; conduct full inspection and grade classification before warehousing on products produced through outsourcing; record the data of each detection node in the management system for products’ quality analysis, traceability, and improvement.

Raw material’s warehousing inspection: IQC

Production process’s quality inspection: OPQC&IPQC

Products warehousing quality inspection:FQC

Product outbound quality inspection:OQC

Packing and shipping

1

Visual Inspection on the casting & forging

2

Dimension Inspection on casting & forging

3

Chemical Analysis & PMI inspection

4

Mechanical Examination

5

Quality inspection in machining & assembling

6

NDT testing

11

ISO 10204: 3.1/3.2 material certification

10

Packing inspection

9

Final Inspection before the shipment

8

Painting inspection

7

Pressure Testing

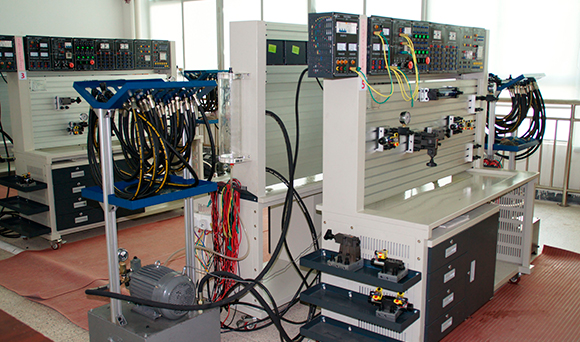

TESTING EQUIPMENT

We have a professional quality control and testing department equipped with professional hydraulic testing equipment, including CMM measuring instruments, hardness testing tables, 3D projectors, internal hole accuracy testers, coordinate measuring instruments, profilometers and spectrometers, pressure testing machines and salt spray testing machines. We strictly follow industry application standards for real-time testing to ensure that the quality of each batch of products is always within a controlled range.

•Visual Inspection

•Dimension Inspection

•Chemical Analysis & PMI •inspection

•Mechanical Examination impact testing

Mechanical Examination Tensile testing

•NDT testing

MORE TESTING EQUIPMENT

HUACHENG on the quality, cost ,delivery and service.