The accessories described here are mainly used in products related to our company (HUACHENG). For different products, they may be gaskets, O-rings, or combination gaskets. Their materials can be rubber, copper, or alloy. When choosing them, in addition to referring to standard guidelines, we also need to judge based on actual application scenarios. This helps us to more effectively improve the product’s service life and prevent leaks. We will choose better materials to make them, which can effectively prevent the leakage of liquids or gases, so they can establish reliable connections.

There are various ways in which they can be combined, depending on the structure of the product and the requirements of the application scenario.

• O-ring Face Seal Fittings

◎ 0-ring Face Seal Fitting Instructions

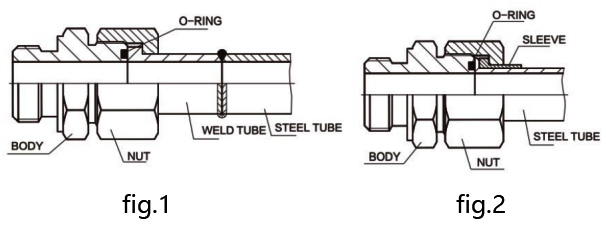

◆The ftting has two types.The firsttype consists of a body,an O-ring,a nut and the weld tube.The weldtube is brazed with the system steel tube,see Fig.1.The second type consists of a body,an O-ring,a nutand a sleeve.Asshown in Fig.2,thetubeis flanged to 90°.When used as Fig.1,the quality of weld is very imporant.

◆O-ring face seal fittings are suit for high pressure system.If the hardness of O-ring is N90, the sealing will better, and be good for preventing leakage.

◆The O-ring face seal fitting has two connected thread(see P6-22) and ORFS thread (see P254-281).

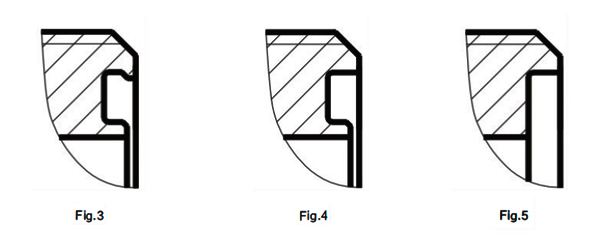

◆As shown in Fig.3, Fig.4 and Fig. 5, the O-ring seal groove has three types. The advantage of type Gig.3.It is very convenience for installation,when put the groove adown O-ring could be held in the groove and not drop; The O-ring could not enter the hydraulic system when the pressure is negative. The type Fig.4 has on the later advantage of the type Fig.3. The type Fig.5 has no above advantage.

◆ Formetric thread O-ring groove JB standardis type Fig.5, butwe suggest thatthe type Fig.3 should be chosen andmake a annotation when order. If no annotation we produce as type Fig. 5 general. For ORFS O-ring groove, we produce as type Fig.3 only.

O–ring Face Seal Fittings Assembly Instructions

◎ Assembly

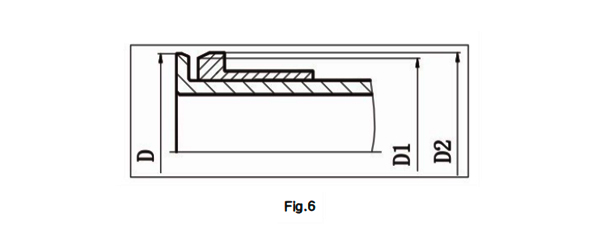

◆ 1As shown in Fig.l,the tube end is cut squarely(within +1-1°)before assemblied,deburr the O.D.and I.D. of the tube,remove all oil and oxide,weld after put the nut .As shown in Fig. 2,the tube is flanged to 90°with special equipment after cut,diameter D should fall between diameter Dl and D2,see Fig. 6.

◆2 .The fitting body should be installed O-ring firstly.

◆3 .As shown in Fig.1 or Fig.2,place tube assembly against the fitting body so that the flat face of the weld tube (or flanged steel tube) comes in full contact with the O-ring. Tighten the nut onto the fitting body by hand, then tighten it to the recommended torque with a torque wrench.If torque wrenches are not available, tighten il/4 to 1/2 turn with general wrench.

◎ Reassembly

◆Because the sealing surf aces are flat and perpendicular to the installtion force,the O-ring may bedistorted during assembly .The O-ring should be in spected at each disassembly and replaced when necessary.

◎ Leakage reason

◆ 1. The O-ring is installed in the face seal groove improperly.

◆ 2. The O-ring is damaged.

◆ 3. The sealing surface,the weld tube or the flange are not flat, or have another fault affecting sealing.

◆ 4. The flange is too large or too small that the O-ring can’t be compressed.

◆ 5. The O-ring material is not suit for working temperature.

◆ 6. The O-ring hardness is not enough.

◆ 7. The connected nut is loosen.

ZHEJIANG HUACHENG HYDRAULIC MECHINERY CO.,LTD.

Our company is the source factory for products such as hose fitting, hydraulic adapters, hose ferrorules, etc., with 23 years of production and sales experience. There is ample stock of products and a wide range of specifications for you to choose from. Our products are well manufactured, without burrs, with perfect threads, high temperature resistance, and corrosion resistance. Welcome to consult and exchange ideas.