- whatsApp:+86 13600292219

- Email: Aden@eakou.com

- Tel:+86-0575-87066777

| Application areas: | Various |

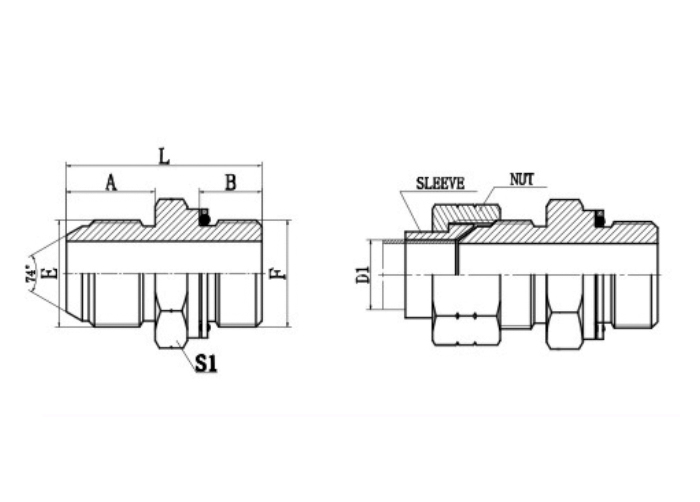

| Product type: | JIC 74°Cone Flared Tube Fittings / BSP MALE O-RING |

| Thread standard:[E:F] |

JIC Male : ORFS Male |

| Structure/Shape: | Straight |

| Basic Material: | Carbon steel、Stainless steel |

| Surface treatment: | Zinc Plating 、Cr3+、Cr6+ |

| Surface color: | White OR Yellow |

| Packaging method: | Moisture-proof plastic bags, Cartons |

| Internal taper of thread: | N/A |

| External taper of thread: | 74° CONE |

| Sealing accessories/material: |

O-ring / Various |

| PART NO. | THREAD | O-RING | DIMENSIONS | ||||

| E | F | F | A | B | L | S1 | |

| 1JG-04-02 | 7/16″×20 | G1/8″×28 | 0011 | 14 | 9.5 | 31 | 14 |

| 1JG-04 | 7/16″×20 | G1/4″×19 | 0111 | 14 | 10 | 32.5 | 19 |

| 1JG-04-06 | 7/16″×20 | G3/8″×19 | 0113 | 14 | 11.5 | 34 | 22 |

| 1JG-04-08 | 7/16″×20 | G1/2″×14 | 0115 | 14 | 14 | 39 | 27 |

| 1JG-05-04 | 1/2″×20 | G1/4″×19 | 0111 | 14 | 10 | 33 | 19 |

| 1JG-05-06 | 1/2″×20 | G3/8″x 19 | 0113 | 14 | 11.5 | 36 | 22 |

| 1JG-05-08 | 1/2″×20 | G1/2″×14 | 0115 | 14 | 14 | 39 | 27 |

| 1JG-06-04 | 9/16″×18 | G1/4″×19 | 0111 | 14.1 | 11 | 31.5 | 19 |

| 1JG-06 | 9/16″×18 | G3/8″×19 | 0113 | 14.1 | 11.5 | 34 | 22 |

| 1JG-06-08 | 9/16″×18 | G1/2″×14 | 0115 | 14.1 | 14 | 39 | 27 |

| 1JG-08-04 | 3/4″×16 | G1/4″×19 | 0111 | 16.7 | 10 | 36 | 22 |

| 1JG-08-06 | 3/4″×16 | G3/8″×19 | 0113 | 16.7 | 11.5 | 37 | 22 |

| 1JG-08 | 3/4″×16 | G1/2″×14 | 0115 | 16.7 | 14 | 42 | 27 |

| 1JG-08-12 | 3/4″×16 | G3/4″×14 | 0119 | 16.7 | 15.5 | 44 | 32 |

| 1JG-10-06 | 7/8″×14 | G3/8″×19 | 0113 | 19.3 | 11.5 | 39.5 | 24 |

| 1JG-10-08 | 7/8″×14 | G1/2″×14 | 0115 | 19.3 | 14 | 44.5 | 27 |

| 1JG-10-12 | 7/8″×14 | G3/4″×14 | 0119 | 19.3 | 15.5 | 48.5 | 32 |

| 1JG-12-08 | 1.1/16″×12 | G1/2″×14 | 0115 | 22 | 14 | 49 | 30 |

| 1JG-12 | 1.1/16″×12 | G3/4″×14 | 0119 | 22 | 15.5 | 49.5 | 32 |

| 1JG-12-16 | 1.1/16″×12 | G1″×11 | 0217 | 22 | 18 | 54 | 41 |

| 1JG-12-20 | 1.1/16″×12 | G1.1/4″×11 | 0222 | 22 | 20 | 57 | 50 |

| 1JG-16-12 | 1.5/16″×12 | G3/4″×14 | 0119 | 23 | 15.5 | 52.5 | 36 |

| 1JG-16 | 1.5/16″×12 | G1″×11 | 0217 | 23 | 18 | 55 | 41 |

| 1JG-16-20 | 1.5/16″×12 | G1.1/4″×11 | 0222 | 23 | 20 | 58 | 50 |

| 1JG-20-16 | 1.5/8″×12 | G1″×11 | 0217 | 24.3 | 18 | 58 | 46 |

| 1JG-20 | 1.5/8″×12 | G1.1/4″×11 | 0222 | 24.3 | 20 | 59.5 | 50 |

| 1JG-24-16 | 1.7/8″×12 | G1″×11 | 0217 | 27.5 | 18 | 63.5 | 50 |

| 1JG-24-20 | 1.7/8″×12 | G1.1/4″×11 | 0222 | 27.5 | 20 | 65.5 | 50 |

| 1JG-24 | 1.7/8″×12 | G1.1/2″×11 | 0224 | 27.5 | 21.5 | 64 | 55 |

| Note: Nut and sleeve should be ordered separately. The nut NB200 and sleeve NB500 is suitable for metric tube, the nut NB200 and sleeve NB300 is suitable for inch tube. | |||||||

The hydraulic adapter products produced by Huacheng have a complete range of specifications and models, complying with international standards such as ISO, DIN, GB, JIS, BSP, BSPT, etc., and are suitable for seamless transition connections of hydraulic pipelines on various equipment such as hard pipes and hoses. The product complies with EATON standards, adopts forging technology, and is 100% CNC machined. Compared with peers, it has advantages such as size standards, extremely small tolerances, materials that meet industry standards, fine surface treatment, and better electroplating technology. Our products include various types and specifications of sealing accessories such as O-ring sealing series, combination gasket sealing series, rubber gasket sealing series, metal (steel, copper) gasket series, etc. In addition to the Metric Thread Bite Type Tube Adapter series, we also produce and sell metric thread O-Ring Face Seal Adpters, Metric Thread 74 ° Cone Flared Tube Adapter, Japanese Metric Thread 60 ° Cone Adapter, and other metric thread series products of different specifications.

Our raw materials can be selected according to the needs of customers’ application scenarios and different products that meet international standards. The difference of raw materials will directly affect the quality of the product, and the concept of our selection of raw materials is: “First of all, it must be guaranteed to be qualified or even exceed the parameters required by the qualified product; Secondly, under the premise of guaranteed quality, we must pursue cost as much as possible; Selecting qualified quality and low-cost raw materials to produce cost-effective products is the quality concept we have always hoped to bring to our customers. “

The main raw materials for the production of our products are: carbon steel and stainless steel, in addition to which we can process products made of brass materials for our customers through outsourcing.

The main raw material models used in carbon steel are: 08AL, Q235, 20#, 35#, 45# and other different models, and different types of raw materials are selected for production according to the specific product quality requirements that need to be delivered.

The main raw material models of stainless steel are: SS304, SS316, etc., and can also be processed according to customer needs.•Using international standard raw materials for processing, the product has a long service life and good air tightness.

Our hose ferrule series products are often used in energy, petrochemical, electric power, shipbuilding, automobile, rail transit, construction machinery, mining, metallurgy, steel mills, marine engineering, machine tool equipment, aerospace, agricultural machinery, textile equipment, electronic entertainment and other industries in hydraulic pipeline systems.

The factory has introduced a number of intelligent robot production lines and a variety of intelligent CNC processing equipment, a total of more than 700 sets.20 years of manufacturing experience, so that we have summarised and accumulated rich experience in manufacturing and research and development, for different products we reserve a complete set of process flow and management methods. From blank processing to product presentation, it is directly completed in the factory, and after strict process control and quality inspection, it can ensure the quality and stability of the product.

All products are automatically processed and formed by CNC machining centre, including cold heading, red punching, punching, chamfering, pipe bending, burr picking and other manufacturing processes, and the products will be processed according to the drawings under the strict control of the quality management department. The production process is divided into six steps: drawing design and validation process, raw material selection and preparation process, semi-finished product production process, CNC machining centre production process, burr and rarity removal process, galvanising and warehousing inspection process, outbound quality inspection and packaging process. These daily tasks help us to establish a good quality control system.

*Any other sizes available on request according to customer drawings!